The ConservEpoxy Brochure

- Repair rather than replace fabric

- Extend the useful life of wood building elements

- Minimize decay development

- Remove and replace only deteriorated areas

- Avoid massive disruption to other components

- Reinforce wood members structurally

- Save time and money

- Preserve our built environment

Flexible Epoxy Consolidant 100

DESCRIPTION

ConServ Flexible Epoxy Consolidant 100 is a flexible non-structural epoxy system designed for stabilizing decayed wood and making it firm. Its low viscosity and long curing time (3 to 5 days) enhances penetration and increases pot life which makes the application easy. It consolidates soft wood fibers with flexible epoxy. This allows for expansion and contraction as a result of temperature and moisture. W100 is a faster curing version for cold weather applications.

Flexible Epoxy Patch 200

ConServ Flexible Epoxy Patch 200 is a flexible epoxy filler for filling voids and making non-structural and cosmetic repairs in wood. When cured the epoxy is quite pliable and can be easily shaped or formed with typical hand or power tools. The Epoxy Patch 200 acts like wood; it can hold nails and screws and accepts solid stain or paint. Use Flexible Epoxy Consolidant 100 as a base. 200 can be applied to wet or dry 100. Use for a wide variety of wood repairs. Three curing speeds are available.

Structural Epoxy Adhesive 552

ConServ Structural Epoxy Adhesive 552 is a thick multipurpose epoxy paste, designed for surface to surface adhesion of wood, metal and masonry and for imbedding fiberglass rebar to make structural connections, splices and reinforcements. Now it is possible to make simple structural repairs by removing or cutting off sections of wood deterioration and splicing in new sections. Easy to use and fast curing. Packaged in 450 ml dual cartridges and it self mixes using our static mixers.

Structural Epoxy Repair 600

ConServ Structural Epoxy Repair 600 is used for rebuilding or repairing deteriorated structural elements. This low viscosity epoxy has many uses. It can be mixed with sand and aggregate to make an epoxy concrete for casting and reinforcing or used in its liquid form as a consolidant or mixed with our 200-D thickening agent to create an epoxy paste

USE/APPLICATION

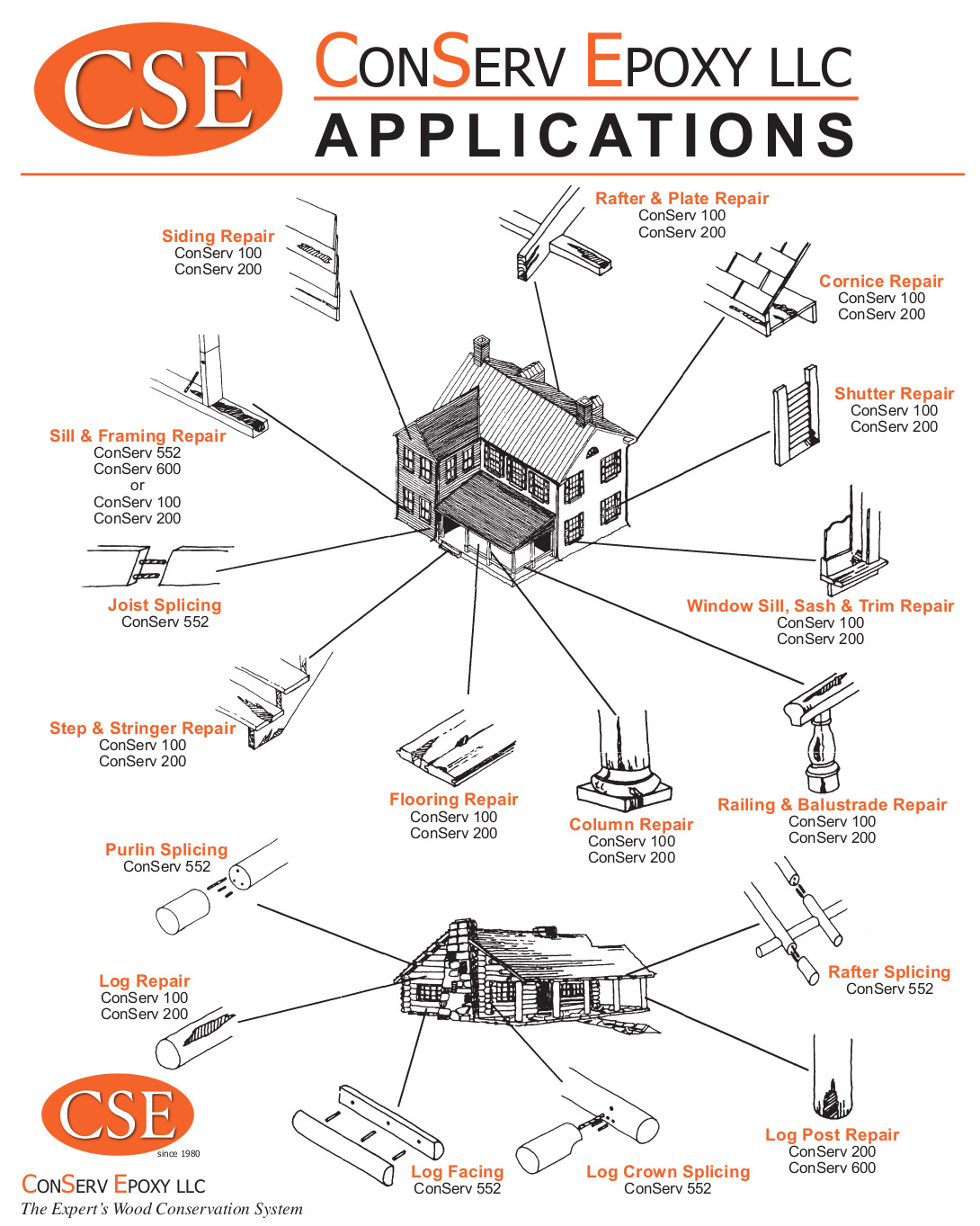

- Window and Door Sills

- Railings and Balustrades

- Porches and Floors

- Framing

- Sash

- Trim and Siding

- Columns and Posts

- Log and Timber Elements

- Stairs and Stringers

- Decorative Ornamental Elements

- Window and Door Sills

- Railings and Balustrades

- Porches and Floors

- Framing

- Sash

- Trim and Siding

- Columns and Posts

- Log and Timber Elements

- Stairs and Stringers

- Decorative Ornamental Elements

- Log Rafters and Purlins

- Log and Timber Facing

- Timber Frame Repair

- Sills and Plates

- Beams and Lintels

- Joists and Framing

- Concrete Pinning

- Vigas

- Fiberglass Rebar Connections

- Timber Frame and Log Repair

- Vigas

- Rafters and Purlins

- Columns and Posts

- Sills and Plates

- Beams and Lintels

- Concrete Pinning

ADVANTAGE

- Penetrates and stabilizes dry wood decay

- Minimizes future decay development

- Flexible - gives with the wood

- Preserves original fabric

- Easy to use

- Rebuilds elements back to original shape

- Flexible - gives with the wood

- Will not shrink

- Easy to form and too

- Can easily adjust the consistency

- Eliminates expensive or difficult scarf joints

- Preserves original fabric

- Simple and cost effective

- Makes amazingly strong connections

- Self mixes and dispenses with static mixers

- Reinforces deteriorated structural elements

- Reduces massive disruption to the building

- Allows for casting of large voids

- Can be used as a structural element

Flower Box Bracket c1913

Wood decay and corroded fasteners removed. ConServ 700 liquid borates were applied due to the extensive wood decay fungus damage.

Wood dried out and saturated with ConServ 100 Flexible Consolidant then filled with ConServ 200 Flexible Patch and tooled smooth once cured.

Bracket repair painted and complete.

2 Speeds 6 sizes

100-1 Flexible Epoxy Consolidant 100 1/2 Gallon

100-6 Flexible Epoxy Consolidant 100 2 fl oz

3 Speeds 6 sizes

200-1 Flexible Epoxy Patch 200 3/4 Gallon

200-6 Flexible Epoxy Patch 200 3 fl oz

552 Epoxy Adhesive 552 450 ml dual cartridge

7 sizes

600-1 Structural Epoxy Repair 600 10 Gallon Set

600-2 Structural Epoxy Repair 600 2 Gallon Set

600-7 Structural Epoxy Repair 600 1/2 Pint Set

800-8 Fiberglass Rebar (5’ lengths) 1” dia.

800-7 Fiberglass Rebar (5’ lengths) 7/8” dia.

800-6 Fiberglass Rebar (5’ lengths) 3/4” dia.

800-5 Fiberglass Rebar (5’ lengths) 5/8” dia.

800-4 Fiberglass Rebar (5’ lengths) 1/2” dia.

800-3 Fiberglass Rebar (5’ lengths) 3/8” dia.

800-2 Fiberglass Rebar (5’ lengths) 1/4” dia.

Longer lengths available

Some of our other products:

- Borate Preservatives

- Mini Hawks

- Static Mixers

- Empty Cans, Bottles and Caulk Tubes

- Disposable Gloves and more

Ordering:

Online: www.conservepoxy.com

Phone: 203-484-4123

Fax: 203-484-2398

Orders are shipped promptly by United Parcel Service (UPS)

Product Information:

ConServ Epoxy LLC realizes that not everyone has experience with epoxies for wood conservation. There is lots of information available on our website. Read the epoxy instruction sheets then call us for more information or guidance on specific applications. We will be glad to share our experience.

Remove paint and soft punky decay. Clean all surfaces and allow wood to dry before epoxy treatment. Apply ConServ Flexible Epoxy 100 by pouring, brushing or spraying. Saturate affected areas continually until the wood reaches fiber saturation and will take no more epoxy.

First saturate the areas to be patched with ConServ Flexible Epoxy 100. ConServ Flexible Epoxy 200 can be mixed to achieve the desired consistency to fill voids, cracks and damaged edges. Apply with a putty knife or cast in place using temporary forms covered with release agents such as clear packing tape, paste wax, polyethylene, wax paper, etc.

Remove deteriorated portions and prepare replacement wood sections. Drill holes to receive epoxy and fiberglass rebar. Make the hole’s diameter 1/4” to 3/8” larger than rebar and the depth 1/2” deeper at each end. Clean out loose debris and inject ConServ Epoxy Adhesive 552 to approximately 70% of hole capacity. Insert rebar and assemble.

ConServ Structural Epoxy Repair 600 can be used as a consolidant, epoxy paste or for casting large voids in wood. For consolidating, prepare and apply like ConServ 100. For repairing and rebuilding structural wood elements, remove the decayed wood, imbed fiberglass rebar to provide reinforcement, and cast void with ConServ 600 mixed with sand and fine aggregate plus a little 200-D to thicken.

www.conservepoxy.com - P.O. Box 454, Northford, CT - Ph: 203-484-4123 - Fax: 203-484-2398